Tungsten carbide, mainly composed of tungsten carbide (WC) and metal binders such as cobalt (Co) produced through powder metallurgy, exhibits high hardness (HRA 89–94), wear resistance, corrosion resistance, and excellent high-temperature stability. These properties make it an ideal material for the core components of high-precision ball valves, widely used in demanding conditions across industries such as oil, chemical, natural gas, and power generation.

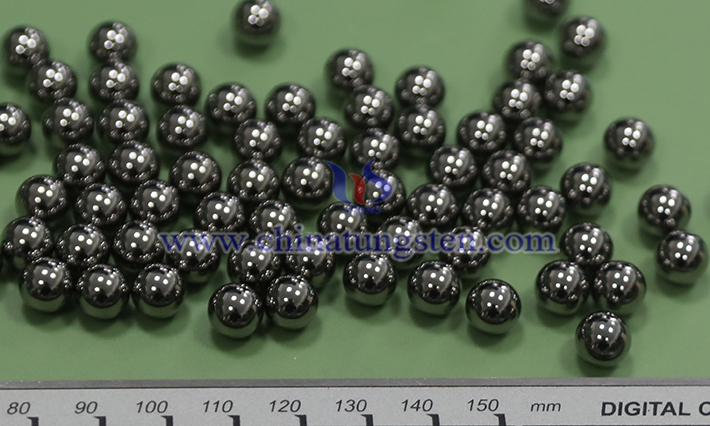

In high-precision ball valves, tungsten carbide balls serve as the valve core, working with the valve seat to form a sealing pair that controls fluid flow and shutoff. Their main advantages include the following:

1. High Wear Resistance and Long Lifespan: The extremely high surface hardness of tungsten carbide balls enables them to resist erosion and wear from high-velocity fluids, particulate matter, or corrosive media. In industries like petrochemicals, where fluids often contain sand, impurities, or highly corrosive chemicals, ordinary metal balls are prone to wear and failure. Tungsten carbide balls significantly extend valve lifespan and reduce maintenance costs.

2. Superior Sealing Performance: High-precision ball valves demand exceptional sealing capabilities. Tungsten carbide balls, through precision grinding, achieve a high surface finish, forming a near-perfect contact surface with the valve seat to ensure zero or extremely low leakage rates. This is critical for controlling high-pressure, high-temperature, or toxic media.

3. Corrosion and High-Temperature Resistance: Tungsten carbide balls withstand corrosion from acids, alkalis, salts, and other aggressive media while maintaining stable mechanical properties in high-temperature environments. For example, in petrochemical cracking furnaces or high-temperature steam pipelines, tungsten carbide ball valves operate reliably under demanding conditions.

4. High-Precision Machining and Reliability: Tungsten carbide balls can be machined into high-precision spheres using advanced CNC grinding and polishing techniques, with roundness errors controlled at the micrometer level. This precision ensures smooth operation and rapid response during frequent valve opening/closing or flow regulation, minimizing the risk of sticking or leakage.