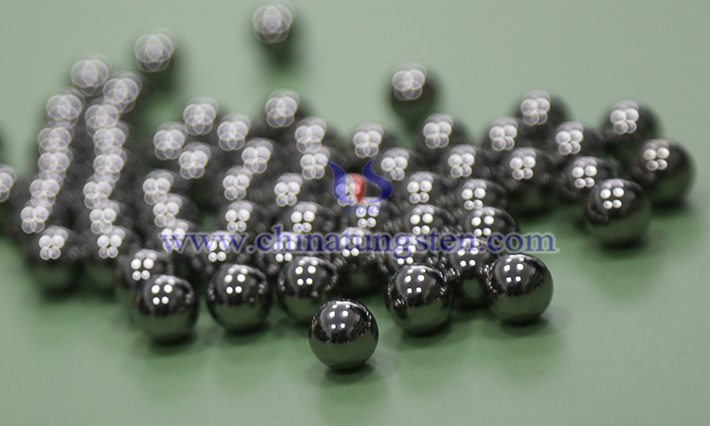

With their high hardness, wear resistance, corrosion resistance, precision, and high load-bearing capacity, tungsten carbide balls are indispensable components in precision bearings. Their application significantly improves bearing performance and longevity, making them widely used in high-end manufacturing, aerospace, precision instruments, and other fields, providing reliable technical support for modern industry.

The role of tungsten carbide balls in precision bearings is mainly reflected in the following aspects:

1. High Hardness and Wear Resistance

Tungsten carbide balls are typically made from high-hardness materials such as tungsten carbide (WC), with a hardness of HRA 89–92, far exceeding that of ordinary steel balls. This high hardness enables them to effectively resist wear under high-speed rotation and heavy loads, extending the service life of bearings. In precision bearings, tungsten carbide balls can withstand high-frequency vibrations and continuous friction, ensuring smooth operation and reducing maintenance frequency.

2. Excellent Corrosion Resistance

Tungsten carbide balls exhibit excellent chemical stability, maintaining performance in harsh environments such as humidity or acidic/alkaline conditions. Precision bearings are often used in demanding applications like aerospace and medical equipment, where the corrosion resistance of tungsten carbide balls ensures sustained precision and reliability, preventing performance degradation due to corrosion.

3. High Precision and Low Friction

Tungsten carbide balls are manufactured with high precision, achieving surface finishes at G5 or even G3 levels with minimal diameter tolerances. This high precision ensures low-friction operation in bearings, reducing energy loss and improving transmission efficiency. In high-speed precision equipment, such as machine tool spindles or turbine engines, tungsten carbide balls significantly reduce frictional heat, maintaining system stability.

4. High Load-Bearing Capacity

Tungsten carbide balls possess extremely high compressive strength, capable of withstanding significant radial and axial loads. In precision bearings, they distribute loads through point or line contact, reducing stress concentration, thereby enhancing the bearing’s load-bearing capacity and impact resistance. This makes them suitable for heavy machinery and high-speed equipment.

5. Thermal and Dimensional Stability

Tungsten carbide balls maintain dimensional and mechanical stability under high temperatures, resisting deformation. This is particularly important for precision bearings operating in high-temperature environments, ensuring accurate performance under extreme conditions.