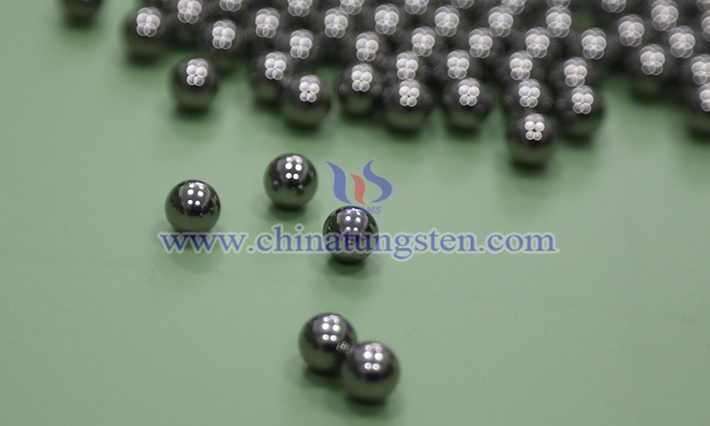

Tungsten carbide balls are widely used in precision bearings, valves, grinding media, nozzles and measuring instruments due to their excellent mechanical properties such as high hardness, high strength, wear resistance, corrosion resistance and impact resistance.

1. High Hardness

Tungsten carbide balls exhibit extremely high hardness, typically with a Vickers hardness (HV) of 1400–1800, approaching that of diamond. This is attributed to the high hardness of tungsten carbide and the toughening effect of the binder phase, making them resistant to deformation under high loads. They are ideal for applications such as grinding and valve sealing.

2. High Compressive Strength

Tungsten carbide balls have a compressive strength of 4000–6000 MPa, far surpassing that of ordinary steel. This enables them to withstand extreme pressures, making them suitable for components like precision bearings and high-pressure pump valves, ensuring structural stability under heavy loads.

3. Excellent Wear Resistance

Thanks to the ultra-high hardness of tungsten carbide grains and the toughness of the binder phase, tungsten carbide balls perform exceptionally well under friction and wear conditions. Their surface wear rate is extremely low, making them ideal for high-wear environments, such as grinding media in ball mills or wear-resistant components in oil drilling.

4. Corrosion Resistance

Tungsten carbide balls offer good resistance to acids, alkalis, and various chemical substances, particularly with an appropriate cobalt content. This enables long-term use in harsh chemical environments, making them widely used in chemical equipment.

5. Impact Resistance and Toughness

By optimizing cobalt content (typically 6%–12%), tungsten carbide balls maintain high hardness while possessing sufficient toughness to resist impact loads and avoid brittle fracture. This ensures performance under dynamic loads, such as in impact drilling applications.

6. High-Temperature Performance

Tungsten carbide balls retain high hardness and strength at elevated temperatures, with operating temperatures reaching 500–800°C. This makes them suitable for high-temperature, high-pressure environments, such as aerospace components or high-temperature valves.

Influencing Factors

The mechanical properties of tungsten carbide balls are influenced by composition, grain size, and manufacturing processes. Finer grains enhance hardness and wear resistance, while higher cobalt content improves toughness but may reduce hardness. Optimized sintering processes, such as hot isostatic pressing (HIP), can minimize internal defects, further enhancing performance.