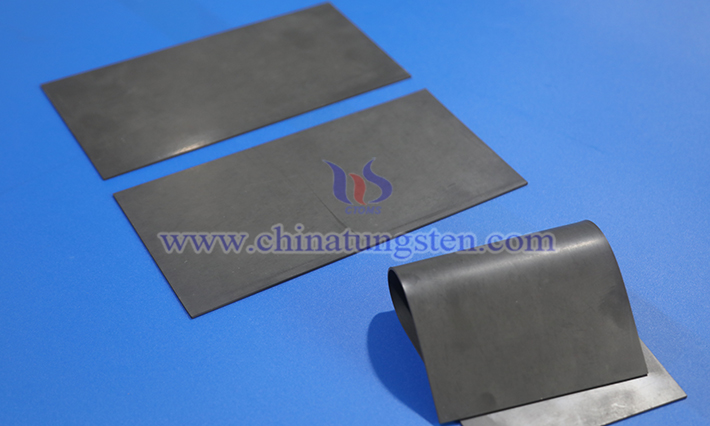

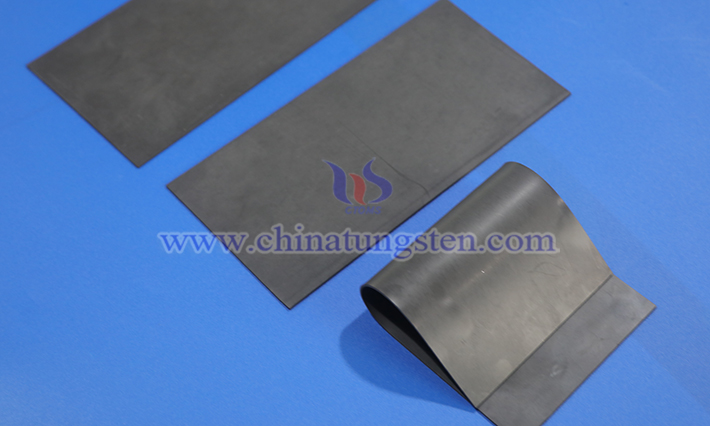

Tungsten resin is a novel composite material whose high-temperature performance primarily depends on the type of resin matrix, the properties of tungsten powder, and the preparation process. Common resin matrices include polyethylene-based resins, epoxy resins, polyurethanes, and specialty resins.

Polyethylene-Based Resin: Polyethylene generally has moderate high-temperature resistance, softening or degrading at lower temperatures, making it suitable for normal or mildly heated environments.

Epoxy Resin: Epoxy resins exhibit better high-temperature resistance, particularly certain modified versions, which maintain structural stability at moderate temperatures, suitable for applications requiring some thermal stability.

Polyurethane: The high-temperature resistance of polyurethane varies by formulation; some high-performance variants can retain mechanical properties at elevated temperatures but generally fall short of specialty resins.

Specialty Resin: Resins like phenolic or polyimide offer excellent high-temperature resistance, maintaining performance at higher temperatures, ideal for specialized scenarios.

The high thermal stability of tungsten powder provides a foundational support for tungsten resin, preventing phase separation or structural damage at high temperatures. However, the thermal decomposition or softening of the resin matrix is the key factor limiting the overall high-temperature performance.

Factors influencing the high-temperature performance of tungsten resin include the choice of resin matrix, tungsten powder content, additives and modifiers, and preparation process.

Resin Matrix Selection: The glass transition temperature and thermal decomposition temperature of different resins affect the high-temperature performance of tungsten resin. For instance, standard polyethylene-based tungsten resin may soften at higher temperatures, while modified phenolic or polyimide-based tungsten resin can withstand more demanding thermal environments.

Tungsten Powder Content: Higher tungsten content enhances the composite's thermal stability due to the powder's inherent resistance to high temperatures. However, excessive tungsten can reduce the resin matrix proportion, decreasing overall flexibility and bonding strength, indirectly impacting mechanical performance at high temperatures.

Additives and Modifiers: Incorporating heat-resistant modifiers (e.g., those containing POSS or tungstic acid) or cross-linking agents can improve the resin's thermal stability, delaying degradation or deformation at high temperatures.

Preparation Process: Process parameters (e.g., curing temperature, mixing uniformity) significantly affect the internal structure of the material. Optimizing the process can reduce porosity and interfacial defects, enhancing stability at high temperatures.