Tungsten alloy collimators, primarily composed of tungsten with nickel, iron, and other elements, exhibit density characteristics surpassing those of collimators made from other materials, giving them a significant advantage in radiation shielding and wide application in the medical field. The application advantages of tungsten alloy collimators include strong radiation shielding capability, excellent radiation durability, environmental friendliness, and superior chemical stability.

Tungsten alloy collimators demonstrate strong radiation shielding capabilities due to their high-density material properties. This high density enables efficient ray blockage, controlling the range of radiation to prevent random dispersion. Whether in medical radiotherapy or industrial inspection scenarios, this characteristic effectively shields excess radiation, reducing its impact on the surrounding environment and non-target areas. Even in continuous radiation environments, tungsten alloy maintains superior structural stability compared to lead, avoiding additional radiation interference over long-term use, thus ensuring reliable equipment operation.

Tungsten alloy is a non-toxic material that poses minimal environmental harm during production, use, and disposal, aligning with the high safety standards required in medical and industrial fields.

Directional Focusing Function: In medical radiotherapy equipment, tungsten alloy allows dynamic blade adjustment to align the radiation beam precisely with the lesion contour. In imaging devices, the front-end structure controls the beam shape to limit the scan range, while the rear-end structure filters stray radiation, enhancing image purity.

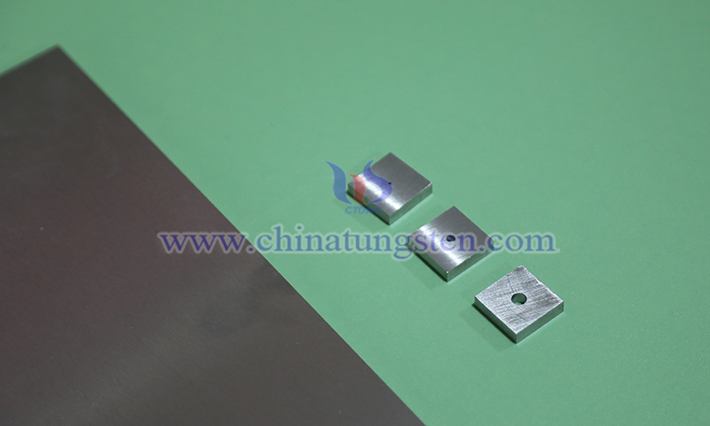

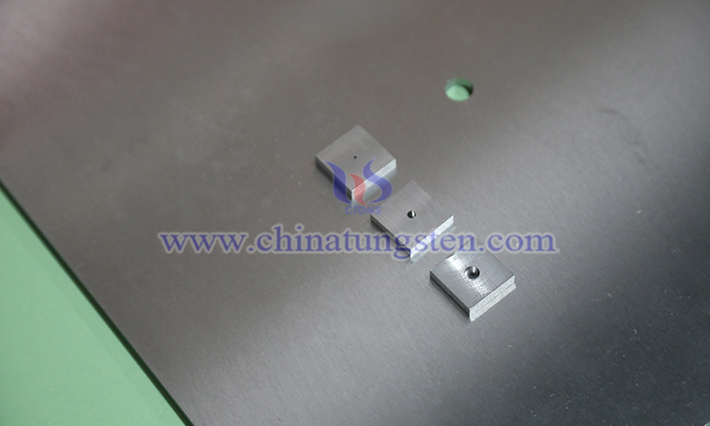

Imaging Support: The pinhole design utilizes the directional projection principle of radiation to achieve high-resolution localized imaging, suitable for detailed scans of small targets or specific organs.

Excellent Mechanical Properties: Tungsten alloy offers strong tensile strength, with optimized processing further enhancing its durability, maintaining shape stability during prolonged high-frequency use to ensure equipment precision.

Outstanding Chemical Stability: In acidic or alkaline environments or frequent contact with disinfectants, it resists corrosion, significantly extending the lifespan of components.