Tungsten is widely used in a variety of fields due to its exceptional hardness, wear resistance, high temperature resistance, corrosion resistance, and high density. Tungsten's uses include:

Cemented carbide: Used in the manufacture of cutting tools, drills, molds, milling cutters, and wear-resistant parts such as cemented carbide inserts; cutting tools and molds, including turning tools, reamers, wire drawing dies, extrusion dies, and stamping dies, are widely used in metalworking, precision casting, and plastic molding.

Aerospace components: Used in the manufacture of rocket nozzles, aircraft engine turbine blades, high-temperature resistant structural parts (such as tungsten alloy counterweights), and thermal protection systems.

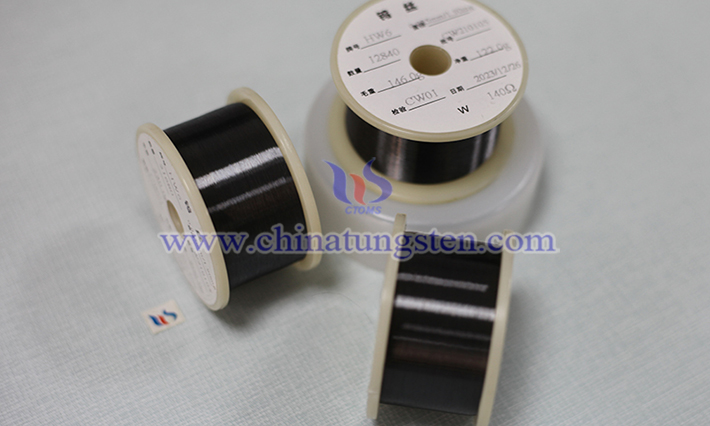

Electronic components: Used in filaments (such as incandescent, fluorescent, and halogen lamps), electron tubes, semiconductor sputtering targets (tungsten targets for chip manufacturing), X-ray tube targets, and vacuum electronics.

New Energy Materials: Photovoltaic tungsten filament (for solar cell cutting), tungsten-copper composites (heat dissipation materials), lithium tungstate cathode materials for solid-state batteries, hydrogen energy equipment components, and wind turbine bearings.

Chemical and High-Temperature Industries: Manufacturing high-temperature furnace heating elements, thermocouple protection sleeves, corrosion-resistant chemical reactors, and high-temperature catalyst carriers.

Medical: Used in radiotherapy devices (such as gamma knives and linear accelerators), medical imaging equipment components (such as CT scanner targets), and radioisotope shielding.

Mining and Geological Exploration: Production of drilling tools, crusher components, tungsten steel drill bits, picks, and mine support structures.

Nuclear Industry: Used in nuclear reactor shielding materials, control rods, nuclear fuel element supports, and radiation protection equipment.

3D Printing and Additive Manufacturing: As a high-performance metal powder, it is used in the manufacture of aerospace components, medical implants (such as hip joints), and complex geometric structures.

Electric Vehicles and Energy Storage: Tungsten alloys, tungsten sulfides, and tungsten oxides have been increasingly used in electric vehicle motor rotors, battery connectors, and wear-resistant components for charging equipment in recent years. Tungsten oxides have found limited application in supercapacitor electrodes, while tungsten sulfides, due to their excellent electrochemical properties, have become a key research and development area in this field.

Optics and Scientific Research: Manufacturing of X-ray equipment mirrors, synchrotron radiation device components, and high-precision optical instruments.

Sports and Consumer Goods: Used in golf club heads, fishing sinkers, and wear-resistant sports equipment.

Marine Engineering: Manufacturing of deep-sea drilling tools and corrosion-resistant offshore platform components.

Chinatungsten Online has long listed cemented carbide and tungsten powder as core industry tracking categories, demonstrating their critical strategic position in the manufacturing and defense industries. Furthermore, tungsten is globally recognized as a strategic key metal. Due to its significant application value in high-tech and defense sectors, it has attracted close attention from countries such as Europe and the United States. Demand continues to grow in semiconductor manufacturing (such as tungsten targets for chips), electric vehicle battery components, nuclear fusion research, and defense equipment. As a critical mineral, tungsten is listed as a priority resource for conservation in the U.S. Critical Minerals List 2022 and the EU Critical Raw Materials Act 2023. Its supply security is crucial to China's economic security and technological independence and control.

For customized tungsten product design and production, please contact China Tungsten Intelligent Manufacturing (sales@chinatungsten.com).

For more information on tungsten, please visit China Tungsten Online (news.chinatungsten.com).