Tungsten resin is a composite material made from high-purity tungsten powder and polymer resin, renowned for its high density, eco-friendliness, and processing flexibility. Lead, as a traditional high-density material, has long been used in industrial, medical, and sports applications due to its low cost and good ductility. However, with growing concerns over environmental regulations and health safety, tungsten resin is increasingly replacing lead.

I. Density and Weight

Tungsten resin has a density range of 11-18 g/cm3, adjustable by varying tungsten powder content, while lead's density is 11.34 g/cm3. This means tungsten resin occupies a smaller volume at the same weight, making it suitable for compact designs such as golf club counterweights or medical shielding components.

II. Mechanical Properties

Tungsten resin's tensile strength exceeds that of lead but is lower than metallic tungsten alloys. Its flexibility comes from the resin matrix, with hardness surpassing lead and greater resistance to deformation, though ductility is less than lead. Lead is easily cast or rolled but prone to scratching and permanent deformation, affecting durability. Tungsten resin's flexibility suits it for protective clothing or complex-shaped counterweights, while lead's softness is better for simple shielding plates.

III. Radiation Shielding Capability

Tungsten resin and lead perform comparably in radiation shielding, with tungsten resin showing a slight edge. Its shielding efficiency improves with higher tungsten content and remains stable for X-ray and β-particle protection. Lead, a traditional shielding material, offers high absorption but requires greater thickness for high-energy γ-rays. Tungsten resin's lightweight and flexible nature makes it preferred in medical (e.g., CT shielding) and nuclear industries (e.g., waste containers).

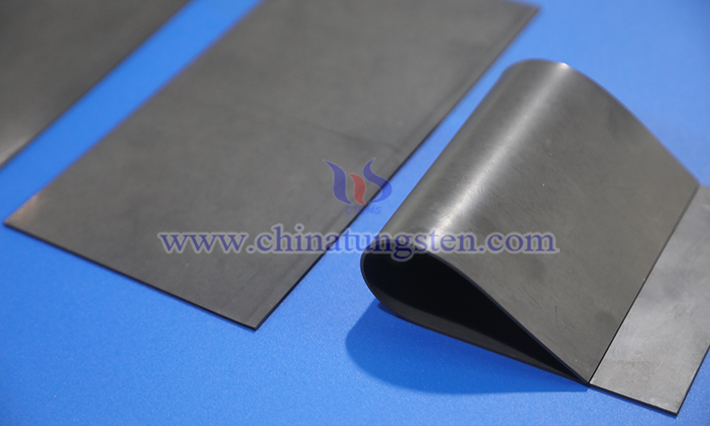

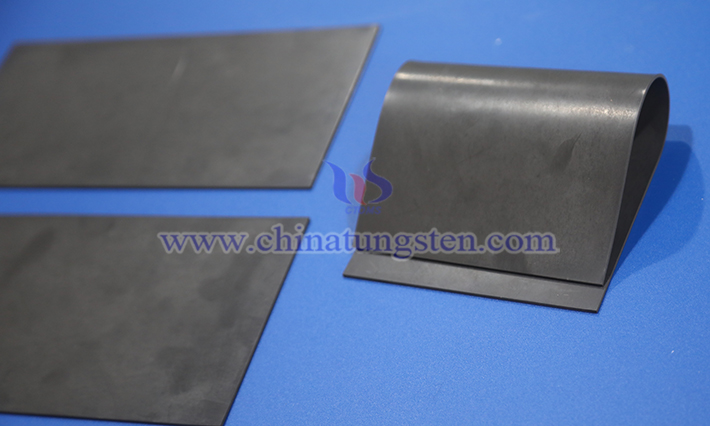

IV. Processability

Tungsten resin's processability significantly outperforms lead. Its resin matrix supports injection molding, extrusion, and 3D printing, enabling the creation of complex shapes like medical syringe covers or teardrop-shaped fishing sinkers. Lead is mainly processed through casting or pressing, making it difficult to form fine or irregular parts.

V. Environmental and Safety Aspects

Tungsten resin's primary advantage is its eco-friendliness. Lead is highly toxic, with long-term exposure causing neurological damage and environmental pollution, requiring strict recycling. Tungsten resin is non-toxic, non-radioactive, meets sustainability standards, and is widely used in medical protective clothing and consumer goods, preventing water or soil contamination.

VI. Corrosion Resistance and Thermal Stability

Tungsten resin excels in humid and chemical environments, being waterproof and resistant to acids and alkalis, suitable for marine (e.g., fishing) and nuclear industries (e.g., waste storage). Lead's surface oxidizes easily, necessitating protective coatings and increasing maintenance costs. In terms of thermal stability, lead has a low melting point and softens at high temperatures; tungsten resin, limited by its resin matrix, typically operates at 150-300°C, with some formulations enduring higher temperatures.

VII. Cost and Economic Efficiency

Lead's cost is significantly lower than tungsten resin due to its abundant resources and simple extraction. Tungsten powder prices are subject to market fluctuations, and processing adds to costs. However, tungsten resin offers better long-term economic value than lead, as it requires no special recycling and its durability reduces replacement frequency.

VIII. Magnetic Properties

Both tungsten resin and lead are non-magnetic, making them suitable for MRI equipment or magnetic-sensitive environments (e.g., archery stabilizers).