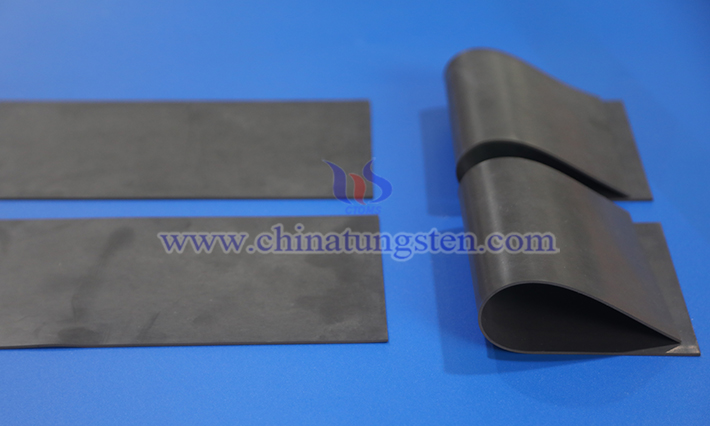

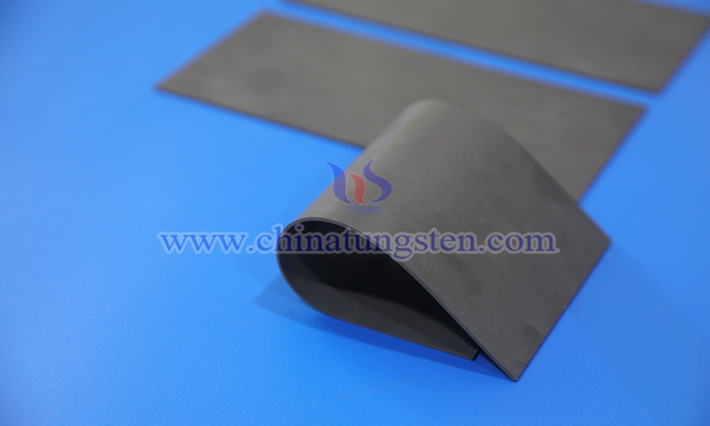

As a novel composite material, tungsten resin is increasingly widely used in the medical field. This material combines the excellent properties of tungsten with the flexibility and ease of processing of resin, creating an efficient and environmentally friendly solution.

In radiation protection, tungsten resin plays a key role. Medical imaging equipment such as X-ray machines and computed tomography scanners often involve radiation exposure, and tungsten resin can serve as a shielding layer to effectively block harmful rays. It is manufactured into protective panels, containers, or casings to shield operators and patients from unnecessary radiation. Compared to traditional shielding materials, tungsten resin is easier to mold, allowing it to adapt to the complex shapes of equipment, ensuring the shielding layer fits closely to the device surface and reducing the risk of radiation leakage.

Another significant application is the manufacturing of medical device components. Tungsten resin is often injected into precision molds to form parts such as catheters, probes, or stents, which need to maintain stability and biocompatibility when used inside the human body. Its strong corrosion resistance enables it to withstand bodily fluid erosion, while its flexibility avoids the discomfort that rigid materials might cause.

In nuclear medicine, tungsten resin also stands out. This field involves the handling and injection of radioactive isotopes, and tungsten resin is used to create syringe shielding sleeves or storage containers. This protective method is highly reliable, as tungsten resin evenly distributes tungsten particles to form a dense shielding network, blocking high-energy radiation like gamma rays. Its processability allows manufacturers to customize the thickness and shape based on the properties of different isotopes, meeting various clinical needs.

Additionally, tungsten resin plays a role in the innovation of diagnostic tools. For example, in magnetic resonance imaging equipment, it is used as a non-magnetic shielding component, effectively preventing interference during device operation. This application expands the scope of tungsten resin, transforming it from a mere shielding material into a multifunctional component.

The application advantage of tungsten resin lies in its environmental friendliness. Traditional radiation protection often relies on heavy metals, whereas tungsten resin reduces environmental burden through composite processes. It is easy to recycle, and its processing is cleaner, aligning with modern medical pursuits of sustainability. Manufacturers can adjust the resin formula to optimize the material's flexibility, meeting the specific needs of various medical scenarios.