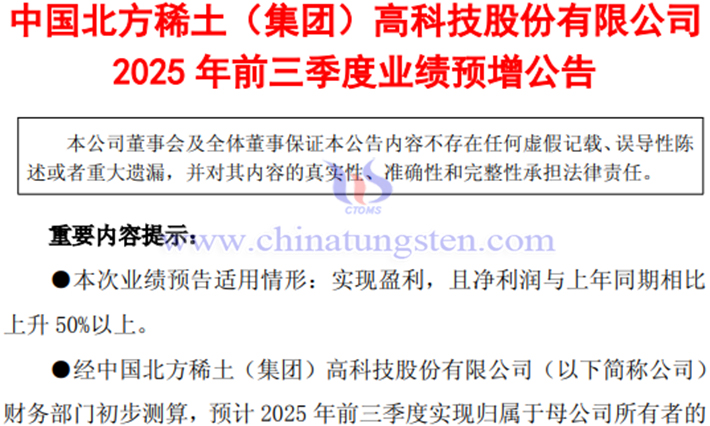

Northern Rare Earth is expected to achieve a net profit attributable to owners of the parent company of 1,510 million yuan to 1,570 million yuan in the first three quarters of 2025, an increase of 1,105 million yuan to 1,165 million yuan compared to the same period last year, representing an increase of 272.54% to 287.34% year-on-year. The net profit attributable to owners of the parent company, excluding non-recurring gains and losses, is projected to be 1,330 million yuan to 1,390 million yuan, an increase of 1,064 million yuan to 1,124 million yuan compared to the same period last year, representing an increase of 399.90% to 422.46% year-on-year.

From January to September 2025, facing a complex and volatile development environment, Northern Rare Earth seized the effective rhythm of market changes, adhered to strategic planning, anchored its annual production and operation targets, strengthened comprehensive budget management, deepened cost reduction and quality enhancement efforts, scientifically coordinated production scheduling, enhanced market research and forecasting, intensified marketing operations to seize market opportunities, accelerated key project construction, promoted research and management innovation, reinforced performance assessment incentives and constraints, and leveraged the stable domestic demand cycle and advantages. Through coordinated strategies and collaborative efforts across production and operation management, the company focused on "forging strengths" to consolidate core competitiveness, addressed "weaknesses" to fill development gaps, solidified development foundations with "quality improvement," and activated growth momentum with "development promotion," laying a solid foundation and providing strong support for a significant year-on-year increase in operating performance.

In terms of production and marketing, Northern Rare Earth adhered to the green development philosophy and the "user-first, brand-supreme" quality principle, advancing a "five-unified" (unified development planning, unified technology sharing, unified production planning, unified raw material supply, unified coordinated maintenance) scientific production model. The company strengthened production system management, adjusted product structures, upgraded process technologies, continuously optimized product portfolios, and promoted high value-added products tailored to specialized, customized, and distinctive market demands. It implemented multi-dimensional benchmarking management, enhanced full-process cost benchmarking upgrades, reducing the overall cost of rare earth processing year-on-year. The company ensured raw material product supply, oriented toward market demand, deepened marketing model innovation, intensified marketing efforts, actively reduced inventory through various measures, and achieved varying degrees of year-on-year growth in production and sales of major products such as smelting and separation, rare earth metals, rare earth functional materials, and permanent magnet motors, providing energy-saving and carbon-reducing rare earth material options for the new energy sector. In terms of key project construction, the company fully consolidated its scale advantages, accelerated the construction of key projects, with the first phase of the next-generation rare earth green mining and smelting upgrade project entering the final stage of production line linkage debugging, and the second phase starting construction and progressing rapidly. Chain-extension, merger and acquisition, joint venture, and capital operation projects for industrial chain enhancement were efficiently advanced. In research and innovation, the company continued to forge scientific research strengths, achieving fruitful innovation results, organizing 20 national-level project applications and 25 regional-level project applications, undertaking and participating in 5 national-level projects and 35 regional-level projects, revising 49 standards, and filing 145 patents, continuously elevating its contribution to national and regional major scientific and technological strategies. It strengthened technological R&D, driving iterative upgrades in process technologies and equipment manufacturing capabilities.